Maximum working fluid pressure: 120 psi (0.83 MPa, 8.3 bar)

Maximum working air pressure: 120 psi (0.83 MPa, 8.3 bar)

Maximum free flow: 897 LPM (237 GPM)

Displacement per cycle: 10.03 liter (2.65 galon)

Maximum conveying solid diameter: 9.5 mm (3 / 8 '')

Maximum dry suction height: 5.4 m (17.6 ft)

Noise level: 86.3 dB (a)

Air inlet size: 3 / 4 in.npt (f)

Air outlet size: 1-1 / 2 in.npt (f)

Fluid inlet size: 3 in.npt (f)

Fluid outlet size: 3 in.npt (f)

Product size (length × width × height): 455.1 mm (17-15 / 16 '') × 330.2 mm (13 '') × 669.5 mm (26-3 / 8 '')

Weight: 100.8 kg (222.2 lbs)

Purpose:

Chemical industry: acid, alkali, solvent, suspension, dispersion system.

Petrochemical Industry: heavy oil, grease, mud, sludge, etc.

Coating industry: resin, solvent, colorant, paint, etc.

Daily chemical industry: detergent, shampoo, emulsion, emulsion, hand cream, surface activator.

Ceramic industry: mud, porcelain slurry, lime slurry, clay slurry.

Mining industry: coal slurry, magma, mud, mortar, lubricating oil, etc.

Water treatment: lime slurry, soft sediment, sewage, chemicals, wastewater.

Food industry: liquid semi-solid, chocolate, salt water, vinegar, syrup, rapeseed oil, soybean oil, honey.

Beverage industry: yeast, syrup, concentrate, gas-liquid mixture, wine, juice, corn syrup, etc.

Pharmaceutical industry: solvent, acid, alkali, plant extract, ointment and other pharmaceutical materials.

Paper industry: binder, resin, paint, ink, pigment, hydrogen peroxide, etc.

Electronic industry: solvent, electroplating solution, cleaning fluid, nitric acid, waste acid, corrosive acid, polishing fluid.

Textile industry: dye chemicals, resins, adhesives, etc.

Construction industry: cement slurry, ceramic tile binder, rock slurry, ceiling finish, etc.

Automotive Industry: polishing emulsion, oil, coolant, automotive primer, oil emulsion, varnish, varnish additive, degreasing fluid, paint, etc.

Furniture industry: binder, varnish, dispersion system, solvent, color agent, white wood glue, epoxy resin, starch binder.

Metallurgy, casting and dyeing industry: metal pulp, hydroxide and carbonization pulp, dust washing pulp, etc.

1. Pneumatic diaphragm pump will not produce electric spark: pneumatic diaphragm pump does not use electric power as power, and prevents electrostatic spark after grounding.

2. Will not overheat: compressed air for power, in the exhaust is a process of expansion and heat absorption, pneumatic pump work temperature is reduced, no harmful gas emissions

3. Can pass through the liquid containing particles: because the volume type work and the inlet is the ball valve, it is not easy to be blocked.

4. The shear force of material is very low: how to suck in and how to spit out when working, so the agitation of material is minimum, which is suitable for the transportation of unstable materials

5. The flow rate can be adjusted. A throttle valve can be installed at the outlet of the material to adjust the flow rate.

6. The pneumatic diaphragm pump has the function of self-priming.

7. It can run empty without danger.

8. You can dive.

9. Pneumatic diaphragm pump can transport a wide range of fluids, from low viscosity to high viscosity, from corrosive to viscous.

10. No complicated control system, no cables, no fuses, etc.

11. The pneumatic diaphragm pump is small in volume, light in weight and easy to move.

12. There is no need for lubrication, so it is easy to maintain and will not pollute the working environment due to dripping.

13. 100% energy utilization, when the outlet is closed, the pump will stop automatically, and the equipment will move, wear, overload and heat

14. Pneumatic diaphragm pump can always maintain high efficiency, and will not be reduced due to wear.

15. The pneumatic diaphragm pump has no dynamic seal, easy to maintain and avoid leakage. There is no dead center when working.

1、 Empty pump test:

After the new pump is connected with the air source, the air supply should be slow from small to large, especially for the small pumps of half inch and 1 inch. The empty time should not be long and the air pressure should not be high to prevent damage to the valve ball.

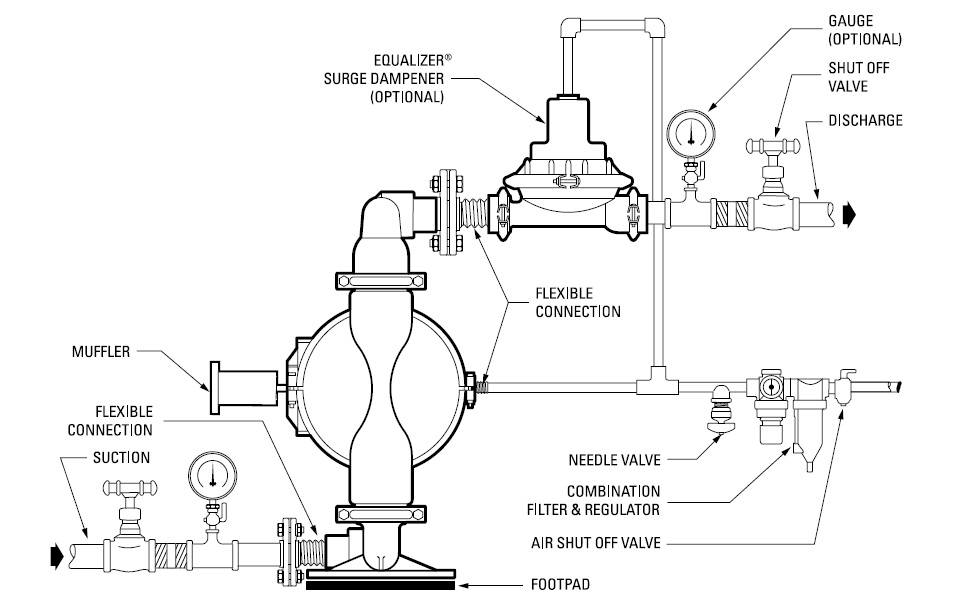

2、 Pump installation:

Install the pump on a flat table, fix the foot, and connect the material inlet and outlet pipe (suggestion for material inlet and outlet: install 30-50cm long elastic hose (or flexible joint) to protect the pump, reduce and reduce vibration, avoid bolt loosening and leakage), tighten all screws on diaphragm pump (to prevent bolt loosening during transportation), and then connect air source.

3、 Protection of gas source:

The air source should be pure (water free, oil-free and dust-free), especially to prevent hard materials such as sand, dust and rust from entering the valve, otherwise the valve will wear away quickly. It is recommended to install a pressure regulating filter at the air inlet of the pump to control and filter the air source; The most common causes of diaphragm pump not working are that the pilot valve is blocked by dirt and the main gas valve is damaged and leaked prematurely. This is mainly caused by the foreign matters (oil, dust, rust water, etc.) in the gas source entering the gas valve. There is usually a certain amount of moisture in the air, which is easy to form rust water in the iron gas pipeline and enter the pump to block and wear the valve. Therefore, it is recommended to install the pressure regulating filter in front of each diaphragm pump (the filter at the outlet of air compressor or air storage tank is not enough) - the filtration accuracy of the pump with more than 1 "port shall not be less than 40 um, and that of the pump with diameter less than 3 / 4" shall not be less than 20 um. Before installation, the air source pipeline must be cleaned to ensure that it is clean and free of impurities. Regularly check the air source filter, regularly clean the impurities in the filter bottle according to the actual working conditions, and replace the filter element regularly to ensure the cleanness of the air source. In addition, the accumulated water in the air compressor and gas pipeline should be removed regularly to ensure that the dry and pure gas enters the pump body.

4、 Precautions for pump and pipeline coordination:

The material inlet pipe must be sealed in good condition, otherwise it will lead to air entering and not feeding.

5、 Precautions for pump and valve coordination:

The start-up sequence of the pump is: first open the pipeline valve - and then air supply; The closing sequence of the pump is: first close the air source - then close the pipeline valve. The sequence can not be reversed, otherwise the pump valve seal will be damaged and cannot be opened again.

Copyright ? 2021 Shenzhen great tower Industrial Co., Ltd. all rights reservedTechnical support粵ICP備2020110751號SITEMAP

Address:402, building 27, Dafa Industrial Zone, Longxi community, Longgang street, Longgang District, Shenzhen City, Guangdong Province

Copyright ? 2021 Shenzhen great tower Industrial Co., Ltd. all rights reserved